Zinc Electroplating Services: Unleash Protection in Metal

National Plating Company is your premier destination for high-quality zinc electroplating services. We specialize in the art of zinc electroplating, a transformative process that enhances the appearance, durability, and corrosion resistance of your metal parts. With a strong commitment to industry standards, including the ASTM B633 and a wide range of company specifications, we deliver high-quality, precise, consistent, and repeatable results. We understand the importance of delivering exceptional outcomes for your metal parts. With advanced equipment, stringent process controls, and a skilled team, we consistently deliver remarkable zinc electroplating results that meet your exact requirements. At National Plating Company, your satisfaction is our top priority.

The Zinc Electroplating Process: Transforming Metal with Precision

Our zinc electroplating process is meticulously designed to achieve outstanding results for a diverse range of metal components. Through a careful combination of chemical reactions and electrical currents, we deposit a layer of zinc onto the surface of your parts. This not only enhances their aesthetic appeal but also provides a protective barrier against corrosion, ensuring their longevity and performance.

In-House Chemist: Expertise and Innovation

Our team includes a dedicated in-house chemist who possesses extensive knowledge and expertise in metal finishing processes. With their profound understanding of chemical interactions, surface preparations, and electroplating techniques, our chemist plays a crucial role in ensuring the precision, accuracy, and consistency of our zinc electroplating services. Their innovative approach and attention to detail are instrumental in achieving remarkable results.

In-House X-Ray & Salt Spray Testing: Ensuring Precision and Durability

To ensure the highest quality and durability of our zinc electroplated parts, we perform in-house X-ray and salt spray testing. Our X-ray testing allows us to inspect the plating thickness and ensure uniformity across all parts, providing precise and accurate results. Additionally, our salt spray testing simulates harsh environmental conditions, allowing us to evaluate the corrosion resistance and performance of our finishes. With these rigorous testing procedures, we assure that your metal parts will meet the highest standards of quality and durability.

ISO 9001:2015 Certification: Commitment to Quality Assurance

We are proud to be ISO 9001:2015 certified, demonstrating our commitment to maintaining an effective quality management system. This certification signifies our dedication to meeting and exceeding customer expectations, continuous improvement, and delivering high-quality zinc electroplating services. With National Plating Company, you can trust in our commitment to excellence and the consistent quality of our work.

Contact Us: Discover the National Plating Company Difference

Ready to elevate your metal parts with zinc electroplating? Contact National Plating Company today to discuss your zinc electroplating needs. Our knowledgeable team is eager to assist you in transforming your metal components into industry works of art.

Experience Zinc Electroplating Excellence with National Plating Company

- Adherence to ASTM B633 and a wide range of company specifications for top-quality results

- High-quality finishes with enhanced corrosion resistance

- Precise, accurate, and consistent electroplating for exceptional outcomes

- ISO 9001:2015 certification showcasing our commitment to quality assurance

- In-house chemist and testing ensuring expertise, innovation, and attention to detail

Zinc Barrel Plating Example Photo Gallery

(Click on thumbnail to enlarge)

- The Part: Screw Mach Part; 1018 Steel

- Approx Size: .26” x 2.3”; .0345

- Scope: Plate Zinc .002″ without damaging knurl

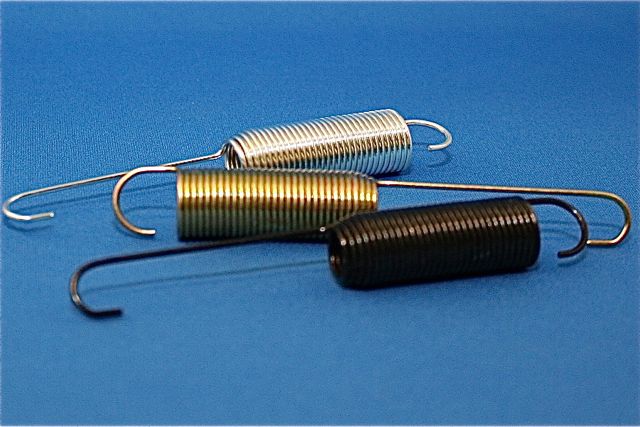

- The Part: Open-end Extension Spring .056″ Music Wire

- Approx Size: .597″ D x 4.42′ L; .038 lb

- Scope: Zinc Plate .0002” MIN; 3 Trivalent Chromates; RoHS Compliant

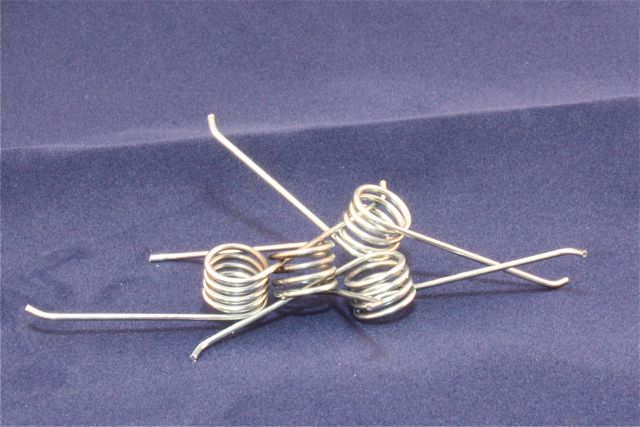

- The Part: Torsion Spring .042” Music Wire

- Approx Size: 41”D x .279 L, .0029 lbs.

- Scope: Zinc Plate .0002” MIN; Clear Trivalent Chromate; RoHS Compliant

- The Part: Stamped Part; 1008 Steel machined 316 SS

- Approx Size: 2” x 4.2” x .209”; .423 lbs.

- Scope: Zinc Plate .0001”-.0003”; Clear Trivalent Chromates; RoHS Compliant

- The Part: Machined Part; 12L14 Steel

- Approx Size: 1”OD/.55”ID x .9”L .115 lbs.

- Scope: Zinc Plate 0001”-.0003”; Clear Trivalent Chromate; RoHS Compliant

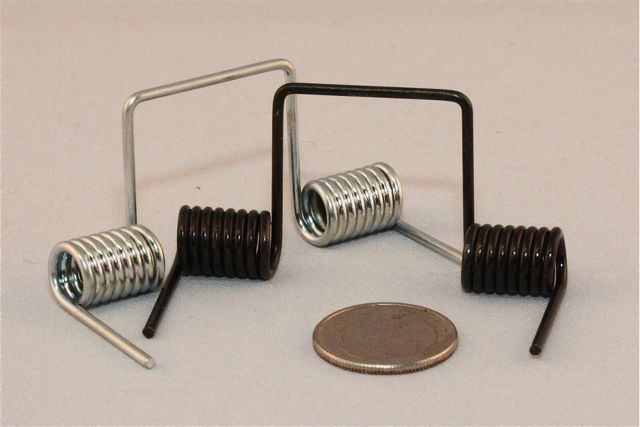

- The Part: Torsion Spring, Music Wire

- Approx Size: .34” D x 1.93” L; .013lbs.

- Scope: Zinc Plate .0002” MIN; Trivalent Chromates; RoHS Compliant

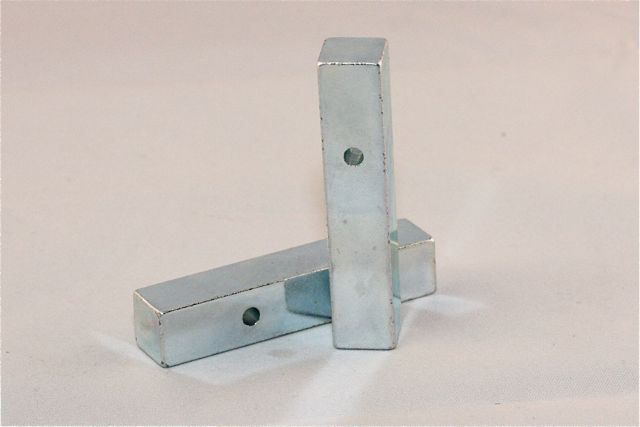

- The Part: Machined Part 12L14 Steel

- Approx Size: .51” x .51” x 2.5”, .172 lbs.

- Scope: Zinc Plate 0005”-.0008”; Clear; Trivalent Chromates; RoHS Compliant

- The Part: Screw Machine Part

12L14 Steel - Approx Size: .25″ D x .775 L; .011 lbs.

- Scope: Zinc Plate .00001”-.0001” Clear Trivalent Chromate RoHS Compliant

Zinc Barrel Plating Service Details

- Plating Material

-

Zinc

- Substrate

-

Copper

BrassSteel

- Plating Characteristics

-

Protection

- Processes

-

Electroplating

- Equipment

-

Barrel

- Pre-Plate Operations

-

Cleaning

- Post-Plate Operations

-

Bake

Hydrogen Embrittlement ReliefChromate Coating

Sealer Coatings

- Zinc Finish

-

Trivalent Clear

Trivalent Yellow

Hexavalent YellowTrivalent Black

Hexavalent Black

Silicate Sealer

- Standards

-

ASTM B633

MIL-T-10727Company Specifications

- Plating Thickness

-

.00001 to .001 in

- Part Length

-

Up to 12 in

- Part Weight

-

Up to 500 lb

- Inspection

-

Wet Lab

X-ray

Plating Thickness

AdhesionCaliper

Micrometer

Thread Gage

- Testing

-

Copper Sulfate

Ferroxyl

Water Immersion24 Hour Humidity

Chemistry

Salt Spray

- Quality Plan

-

Process Steps

Electrical Settings and TimesTest procedures

Photos

- Additional Services

-

Count

Pack

LabelBar Code

Ship

- Production Volume

-

1 to High Volume

- Industry Focus

-

Automotive

Agriculture

Electrical

Food Service

MedicalResearch

Pharmaceutical

Marine

Aerospace

- Intended Application

-

Springs

Fasteners

Pumps

FiltersMechanical Parts

Relays

Contactors

- Industry Standards

-

ISO Compliant

ASTM B912RoHS Compliant

- Environment

-

OSHA Inspection: No Exposure

- File Formats

-

PDF

JPG