Tin Electroplating Services: Elevating Metal Excellence

National Plating Company is your trusted source for superior tin electroplating services. We specialize in bright acid tin electroplating, a process that enhances the appearance, durability, and functionality of your metal parts. With a steadfast adherence to industry standards, including the ASTM B545, MIL-T-10727, ISO 2093, AMS 2408 and most company specifications, we ensure high-quality, precise, consistent, and repeatable results.

The Bright Acid Tin Electroplating Process: A Transformation in Metal

Our bright acid tin electroplating process is designed to provide exceptional results for a wide range of metal parts. Through a meticulous combination of chemical reactions and electrical currents, we deposit a layer of bright and lustrous tin onto the surface of your components. This process not only enhances the aesthetics but also provides a protective coating that improves corrosion resistance and extends the lifespan of your metal parts.

Why Tin Electroplate?

- Corrosion resistance: Tin is highly resistant to corrosion, making it an excellent protective coating for metals that are susceptible to rust and other forms of oxidation. By electroplating a layer of tin onto a metal surface, the tin acts as a barrier, preventing direct contact between the underlying metal and corrosive elements in the environment.

- Solderability: Tin is commonly used in soldering processes, as it forms a reliable and low-resistance connection between electronic components. Electroplating a thin layer of tin onto copper or other base metals enhances their solderability, ensuring better adhesion and improved electrical conductivity.

- Aesthetics: Tin electroplating can provide a visually appealing and decorative finish to various objects. It imparts a bright, reflective surface that can enhance the appearance of jewelry, tableware, and other items.

- Lubricity: Tin has a low coefficient of friction, meaning it reduces the friction between two surfaces in contact. Electroplating with tin can provide a lubricious surface, reducing wear and tear, improving sliding or rotating components’ performance, and preventing galling or seizing.

- Food contact safety: Tin is a non-toxic material, and electroplating with tin is commonly used for food-grade applications. Tin-lined cookware and food containers ensure that the underlying base metal does not come into direct contact with food, preventing potential reactions or contamination.

Adherence to ASTM B545, MIL-T-10727, and AMS 2408: Setting the Standards for Excellence

At National Plating Company, we take pride in our unwavering commitment to industry standards. We strictly adhere to the ASTM B545, MIL-T-10727, and AMS 2408 specifications, which are recognized as benchmarks for the tin electroplating processes. These standards ensure that our electroplating treatments meet stringent quality requirements, assuring outstanding outcomes for your metal components.

Contact Us: Discover the National Plating Company Difference

Ready to elevate your metal parts with bright acid tin electroplating? Contact National Plating Company today to discuss your tin electroplating needs. Our dedicated team of experts are ready to assist you in transforming your metal components into shining masterpieces.

Experience Tin Electroplating Excellence with National Plating Company:

- Adherence to MIL-T-10727, ASTM B545, and AMS 2408 specifications for top-quality results

- High-quality finishes with bright and lustrous tin coating

- Precise and accurate electroplating for exceptional results

- Consistent and repeatable outcomes for your metal components

Tin Plating Example Photo Gallery

(Click on thumbnail to enlarge)

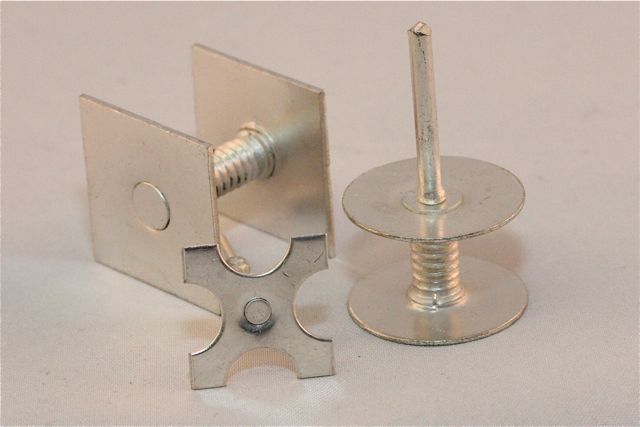

- The Part: Stamped crimp-on connector .032″ Copper

- Approx Size: 49″ across, .0035 lb.

- Scope: Plate Tin .0002″ without damaging part geometry

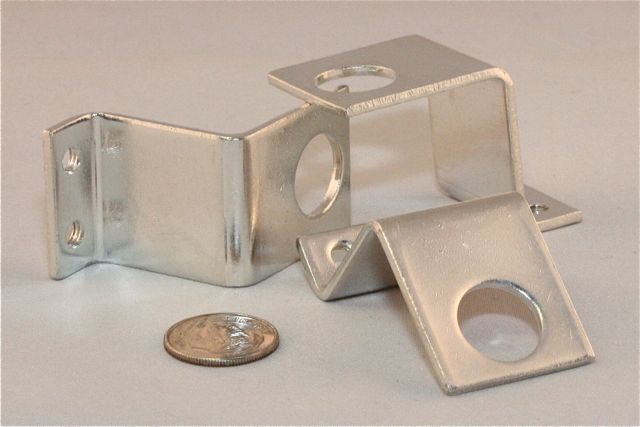

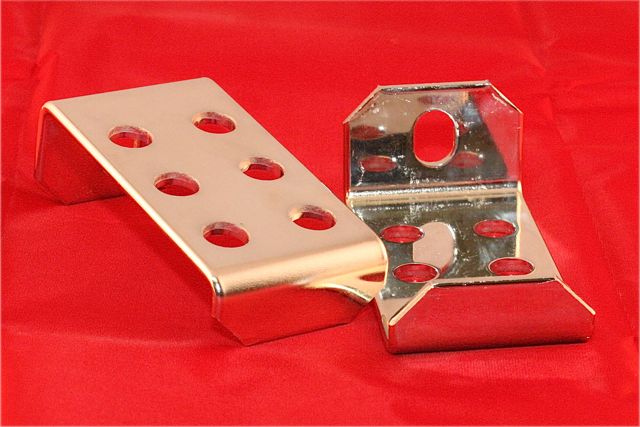

- The Part: Stamped/welded CR Steel

- Approx Size: Small-Large; .005″-.5 lbs.

- Scope: Plate Tin .00005″ (i.e., “Flash”) while covering all surfaces (inc. welds)

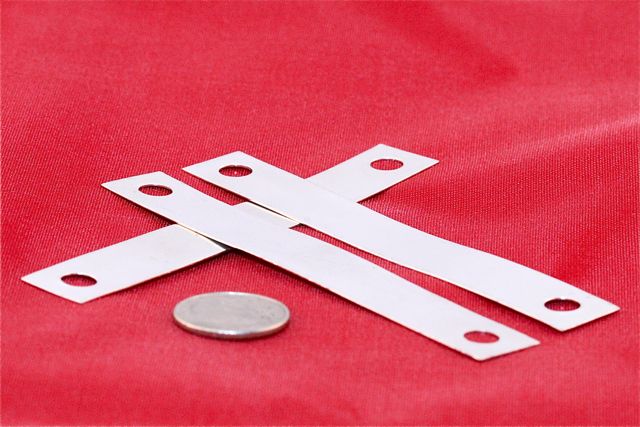

- The Part: Tie-down .027″ Copper

- Approx Size: .7″W x 1.5″L, .012 lbs.

- Scope: Plate Tin .0002″ MIN; without damaging part

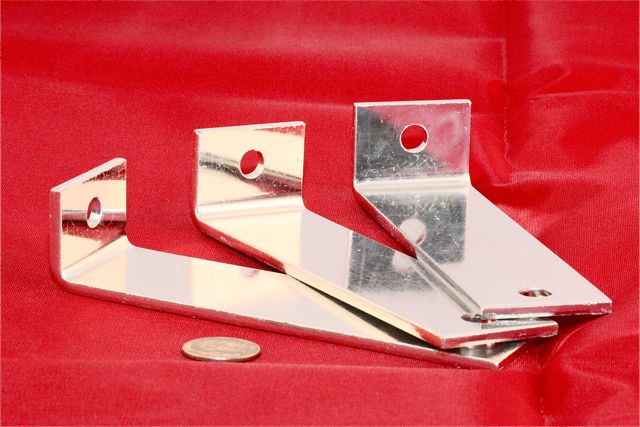

- The Part: Stamped Part .089″ Copper

- Approx Size: 2″ x 4.2″ x .209″, .057 lb.

- Scope: Plate Tin .0001″ – .0003″; Parts are RoHS Compliant

- The Part: Stamped .024″ Copper

- Approx Size: .45″W x 3.5″L; .0089 lb.

- Scope: Plate Tin .0002″ MIN without damaging part

- The Part: Machined .089″ Lead

- Approx Size: 2.6″W x 5.9″L; .35 lb.

- Scope: Plate Tin .0002″ MIN; without damaging very delicate part

- The Part: Stamped .135″ Copper

- Approx Size: 1.25″W x 5.5″L, .26 lb.

- Scope: Plate Tin .0002″ MIN; Parts are RoHS Compliant

- The Part: Precision steel/babbit bearing

- Approx Size: Set of 2 halves

4.5″D x4″L - Scope: Plate Tin .00005″-.0001″; Parts are RoHS Compliant

Tin Plating Service Details

- Plating Material

-

Tin

- Substrate

-

Copper

BrassSteel

Lead

- Plating Characteristics

-

Protection

ConductivitySolderability

- Processes

-

Electropolishing

- Equipment

-

Barrel

Rack

- Pre-Plate Operations

-

Cleaning

- Post-Plate Operations

-

Bake

Hydrogen Embrittlement Relief

- Tin Finish

-

Bright

Acid Matte (Solderable)

- Standards

-

ASTM B545

MIL T-10727Company Specifications

- Plating Thickness

-

.0001in. to .001 in.

- Part Length

-

Barrel: Up to 18 in.

Rack: Up to 30 in.

- Part Weight

-

Up to 500 lb

- Inspection

-

Wet Lab

X-RayPlating Thickness

Adhesion

- Testing

-

Salt Spray

- Quality Plan

-

Racks Used

Process StepsElectrical Settings and times

Photos

- Additional Services

-

Count

Pack

LabelBar Code

Ship

- Production Volume

-

1 to High Volume

- Industry Focus

-

Automotive

Agriculture

Electrical

Food Service

MedicalResearch

Pharmaceutical

Marine

- Intended Application

-

Springs

Chaplets

Radiation Shieldsbr/> Pumps

FiltersRelays

Contactors

Buss Bars

Mechanical Parts

- Industry Standards

-

ISO Compliant

ASTM

ANSI

QQAMS

MIL

RoHS

- Environment

-

OSHA Inspection: No Exposure

- File Formats

-

PDF

JPG