Pickling & Passivation Services

National Plating Company, your premier destination for comprehensive pickling and passivation services for stainless steel. With our unwavering commitment to quality and expertise, we offer a range of solutions that meet the highest industry standards, including compliance with renowned specifications such as ASTM A967, AMS 2700, ASTM A380, QQ-P-35, and various company-specific requirements.

Our pickling and passivation processes are meticulously designed to remove impurities and contaminants from stainless steel surfaces while enhancing their corrosion resistance. With our state-of-the-art facility and a team of skilled professionals, we ensure that each step of the process adheres to the strictest standards and delivers exceptional results.

At the core of our operations is our in-house chemist, whose expertise and knowledge play a pivotal role in developing precise chemical formulations for pickling and passivation. Our chemist conducts thorough chemical testing to ensure optimal performance and adherence to industry specifications, including those outlined by ASTM standards. This rigorous testing guarantees that our pickling and passivation processes effectively meet or exceed the required criteria, providing you with superior quality and long-lasting results.

As part of our commitment to transparency and customer satisfaction, we provide comprehensive documentation for all our pickling and passivation services. This documentation includes detailed process records, chemical compositions, and quality control measurements, allowing you to have complete visibility and traceability of our work.

In addition to our standard testing procedures, we also offer optional additional testing methods to further validate the performance and durability of our pickling and passivation services. These tests include salt spray testing, 24-hour humidity testing, ferroxyl testing, copper sulfate testing, and water immersion testing. These tests are conducted in accordance with the relevant ASTM standards, providing you with reliable and comprehensive data on the corrosion resistance and quality of the treated stainless steel.

At National Plating Company, we are dedicated to providing pickling and passivation solutions that not only meet but exceed industry standards. With our focus on quality, chemical testing by our in-house chemist, comprehensive documentation, and optional additional testing methods, we ensure that your stainless-steel surfaces receive the highest level of care and protection.

Experience the pinnacle of pickling and passivation services with National Plating Company, where excellence, compliance, and customer satisfaction are at the forefront of everything we do.

For more information on our passivating capability, see the table below, or contact us directly.

Passivation Example Photo Gallery

(Click on thumbnail to enlarge)

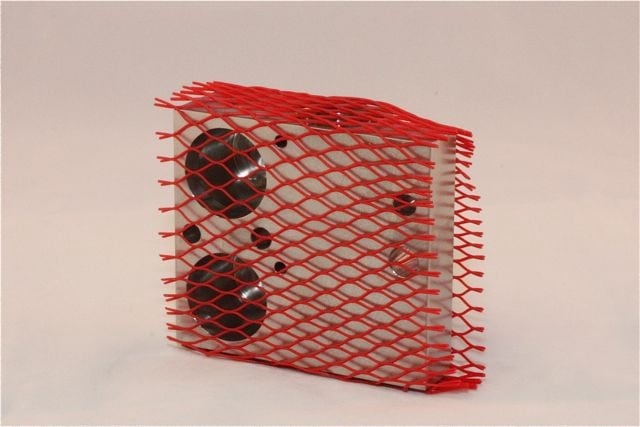

- The Part: Precision machined & Ground 316 SS

- Approx Size: 3.5″ x 5″ x 1.5″, 6 lb.

- Scope: Passivate per ASTM A-967 – No damage to any surface allowed

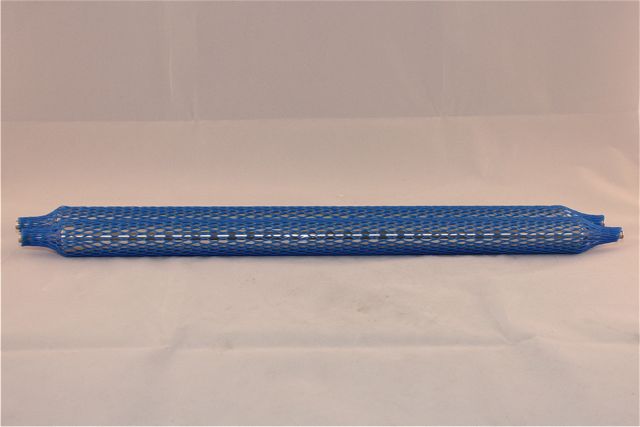

- The Part: Formed & welded pipe assembly 316 SS

- Approx Size: 4″ ID; 60″ long, 60 lb.

- Scope: Passivate inside & outside

- The Part: Welded, machined & ground 304 SS

- Approx Size: Major ID ~3″ 14″L, 10 lb.

- Scope: Passivate inside and outside

- The Part: Machined sand casting 316 SS

- Approx Size: 6″ x 6″ x 10″, 14 lb.

- Scope: Passivate complete & Ferroxyl Test

- The Part: Springs 302, 304, 17-4, 17-7 SS

- Approx Size: Wide variety of sizes & shapes.

- Scope: Passivate complete & Ferroxyl Test

- The Part: Stamped & formed 304 SS

- Approx Size: 12″ Dia. x 3″ High, 3 lb.

- Scope: Passivate complete & Ferroxyl Test

- The Part: Welded/shaped vessel 316 SS

- Approx Size: Major OD 12″ x 40″, 90 lb.

- Scope: Passivate complete-thorough rinsing of inside surfaces is critical

- The Part: Precision turned/ground roller 304 SS

- Approx Size: 1.1″OD x 18″L, 5 lb.

- Scope: Passivate complete-absolutely no surface damage allowed

Passivation Capabilities

- Media

-

Nitric Acid

- Substrate

-

Stainless Steel

- Removes

-

Free Iron

Surface Impurities

- Equipment

-

Temperature Controllers

Digital Timers

- Pre-Operations

-

Cleaning

- Post-Operations

-

Rinsing

- Standards

-

ASTM A967

QQ-P-35

ASTM A380AMS 2700

AAA Passivation

Mil-Spec

- Length

-

Up to 8 ft.

- Width

-

Up to 3.5 ft.

- Height

-

Up to 3.5 ft.

- Part Weight

-

Up to 500 lb

- Testing/Inspection

-

Copper Sulfate

Ferroxyl

Water Immersion24-Hour Humidity

Chemistry

Salt Spray

- Quality Plan

-

Equipment Used

Process StepsElectrical Settings and Times

Photos

- Additional Services

-

Count

Pack

LabelBar Code

Ship

- Production Volume

-

1 to High Volume

- Industry Focus

-

Aerospace

Agriculture

Automotive

Electrical

Food ServiceMarine

Medical

Pharmaceutical

Research

- Intended Application

-

Reduce Friction

Springs

Lead Screws

Shafts

Housings

Bearings

Reduce Product ContaminationFilters

Chambers

Screens

Hydraulics

Pipes

Pumps

Valves

Tanks

- Industry Standards

-

ISO Compliant

ASTM A380

ASTM A967

AAA PassivationQQ-P 35

AMS 2700

RoHS Compliant

Mil-Spec

- Environment

-

OSHA Inspection: No Exposure

- File Formats

-

PDF

JPG