Electropolishing Services: Enhancing Metal Excellence

At National Plating Company, we specialize in providing high-quality electropolishing services that elevate the beauty and functionality of your metal parts. With a meticulous adherence to industry standards, including the ASTM B912 specification, we assure impeccable finishes and consistent results.

The Electropolishing Process: A Transformation in Metal

Electropolishing is a highly effective metal finishing technique that offers a multitude of benefits. Through a combination of chemical and electrolytic processes, we achieve remarkable improvements in surface finish, durability, and corrosion resistance. Our skilled technicians carefully execute each step of the electropolishing process to ensure precision, consistency, and repeatable results. Electropolishing effectively eliminates surface defects such as burrs, pits, and weld discoloration from metal parts. Our precise and controlled processes remove these imperfections, resulting in flawlessly smooth surfaces that are visually striking. Whether it’s intricate medical devices, aerospace components, or industrial equipment, our electropolishing services breathe new life into your metal parts, giving them a refined and pristine appearance.

Adherence to ASTM B912: Setting the Standard for Excellence

At National Plating Company, we are proud to follow the strict guidelines set forth by the ASTM B912 specification. This industry standard ensures that our electropolishing processes meet the highest levels of quality and consistency. By adhering to ASTM B912, we assure that your metal parts undergo a meticulous and reliable electropolishing treatment, resulting in outstanding finishes.

Unleashing the Potential of Stainless Steel: Improved Ra and Corrosion Prevention

One of the key benefits of electropolishing is the dramatic improvement in the surface roughness, measured as Ra, of stainless steel. By removing surface imperfections and microburrs, we achieve a smooth and pristine finish that enhances both aesthetics and functionality. This reduction in Ra not only enhances the visual appeal of your metal parts but also improves their resistance to corrosion, ensuring long-lasting durability and performance.

High-Quality Finishes: Exceeding Expectations

At National Plating Company, we are committed to delivering high-quality finishes that exceed your expectations. Our experienced technicians utilize advanced equipment and techniques to achieve consistently excellent results. We take pride in our ability to provide precise, reliable, and repeatable outcomes for every project, ensuring your complete satisfaction.

Contact Us: Discover the National Plating Company Difference

Ready to experience the brilliance of electropolishing? Contact National Plating Company today to discuss your metal finishing needs. Our team of experts is ready to assist you in transforming your metal parts into shining works of art.

Experience Metal Finishing Excellence with National Plating Company:

- Adherence to ASTM B912 Spec for top-quality results

- Improved Ra for enhanced aesthetics and corrosion resistance

- Elimination of surface defects for flawless metal parts

- High-quality finishes with precision and consistency

Electropolishing Example Photo Gallery

(Click on thumbnail to enlarge)

- The Part: Investment Cast 316 SS

- Approx Size: 2″ x 3″ x 6″; 1 lb.

- Scope: Creating food-safe surface before machining

- The Part: Complex stamped and welded 304 SS

- Approx Size: 18″dia x 5’long; 18 lbs.

- Scope: Improve appearance;

eliminate weld scale & remove burrs

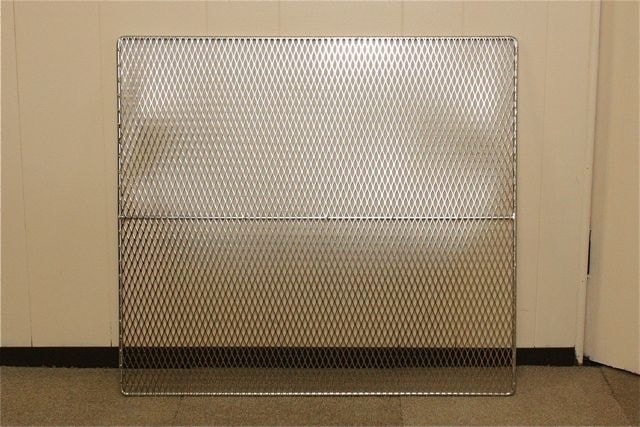

- The Part: Stamped, welded, flat 304 SS

- Approx Size: 26″ x 40″; 10 lbs.

- Scope: Create food-safe surface; remove burrs & eliminate weld scale

- The Part: Sand cast, welded,

machined 316 SS - Approx Size: 12″ Major Dia; 40 lbs.

- Scope: Create food-safe surface inside, outside & eliminate weld scale

- The Part: Earrings–laser cut,, hand polished 316 SS

- Approx Size: See pic;; .04 lbs.

- Scope: Create very highly polished, medically-safe outside surface

- The Part: Forged, welded 316 SS

- Approx Size: 6″dia x 40″long; 28 lbs.

- Scope: Prepare surface for continual saltwater exposure on a yacht

- The Part: Punched, formed, welded 304 SS

- Approx Size: 12″dia x 5″long; 5 lbs.

- Scope: Improve outside appearance; eliminate weld scale & reduce burrs

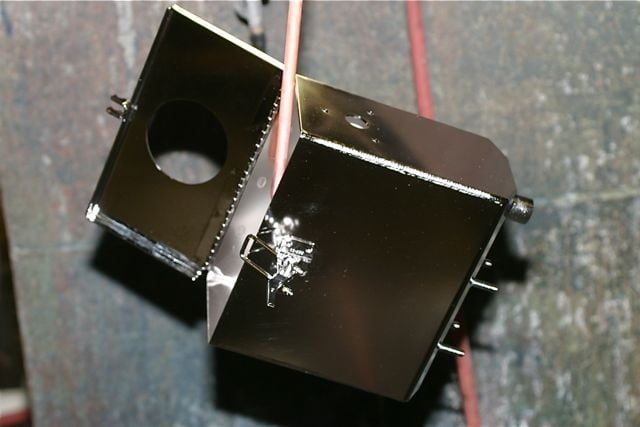

- The Part: Punched, formed, and assembled 304 SS

- Approx Size: 5″ x 5″ x2″, 1.5 lbs.

- Scope: Improve outside appearance, including applied latched, hinges, etc.

Electropolishing Service Details

- Polishing Processes

-

Electropolishing

- Equipment

-

Racks

Temperature ControllersDigital Timers

- Polished Parts

-

Mechanical

Raw Castings

MachinedLaser Cut

Welded

- Finish Designations

-

Down to RMA 8

- Substrate

-

Stainless Steel

301 15-5304 17-4

316 17-7

410 Carpenter 18-FMNitronic 60

- Standards

-

ASTM B912

Company Specifications

- Part Length

-

Up to 40 in

- Part Diameter

-

Up to 22.5 in

- Part Weight

-

Up to 500 lbs.

- Inspection

-

Wet Lab

ProfilometerCaliper

Micrometer

- Testing

-

Ferroxyl

Water Immersion

24 Hour HumidityChemistry

Salt Spray

- Quality Plan

-

Racks Used

Written process StepsElectrical Settings and Times

Photos

- Additional Services

-

Count

Pack

LabelBar Code

Ship

24 Hr Humidity TestSalt Spray Test

- Production Volume

-

1 to High Volume

- Industry Focus

-

Automotive

Trucks

Trains

Aerospace

AgricultureMarine

Food Service

Medical

Pharmaceutical

Research

- Intended Application

-

Pumps

Filters

Tanks

Distillation ChambersMechanical Parts

Scientific Parts

Earrings

Bracelets

- Industry Standards

-

ISO Compliant

ASTM B912RoHS Compliant

- Environment

-

OSHA Inspection: No Exposure

- File Formats

-

PDF

JPG